100w Laser

Consider the power supply's rating on cutting power when researching your cutting abilities. To cut thin sheets, a lower power supply can be used. Material with a greater thickness will need a higher power supply. This helps enterprises control their costs.

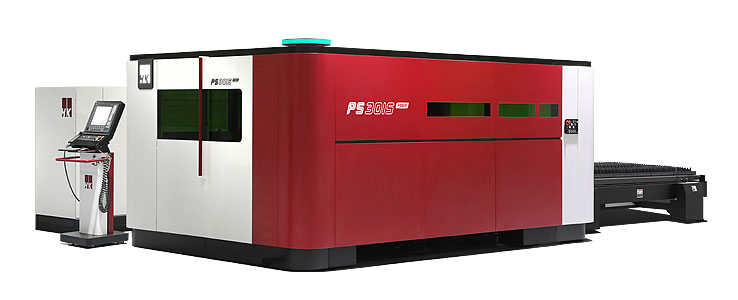

High speed IPG fiber laser cutter is type of high power laser metal cutting machine with 12000W power supply for commercial use of thick metal fabrication including stainless steel, carbon steel, mild steel, tool steel, brass, copper, aluminum, alloy, and rare metals in industrial manufacturing.